MANUFACTURING EXCELLENCE

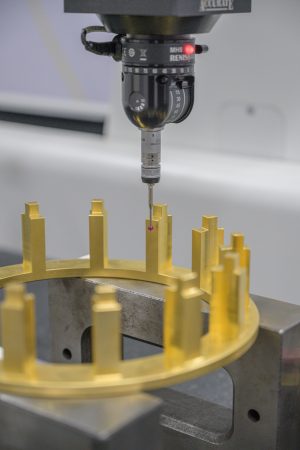

Aeris's manufacturing excellence is based on a philosophy of leveraging cutting-edge technology to develop and manufacture bearing cages and stamped components while focusing on cost, quality, and production flexibility.

Innovation through

R & D

Our Research & Development initiatives have led through to innovations which have been instrumental in improving manufacturing processes, reduced human error, enhanced precision and saved energy across product verticals.

Quality

As Aeris continues its march towards a zero defect environment, it continues to ensure regular assessment, reviews, course correction and retraining to reaffirm its quality focus.

Process & Capabilites

The manufacturing processes leverage a production infrastructure comprising of manual, semiautomatic and fully automatic machines.

Make Excellence

Every product at Aeris is properly documented and quality-checked throughout the whole manufacturing process.

Aeris factories are ISO 9001 certified for the manufacturing and exportation of bearing cages and machined components, ensuring that every batch will satisfy customer requirements.

The in-house toolroom for fixture and tool development helps to ensure the best quality output, even for low quantity batches, while also reducing development time and cost.

An overview of the manufacturing and process capability is provided below.

Measuring instrument & Testing equipment’s

• CNC - CMM

• Surface Roughness Tester

• Gauge Block

• Height Master

• Comparator Stand

• Surface Plate

Our Ability

Meet the Professionals

After brainstorming about insights, get the power to create something real. Bring your ideas to life and share your vision with concrete elements.

Prosperity

Quality

Guarantee

Services